Coating service

UV-coatings

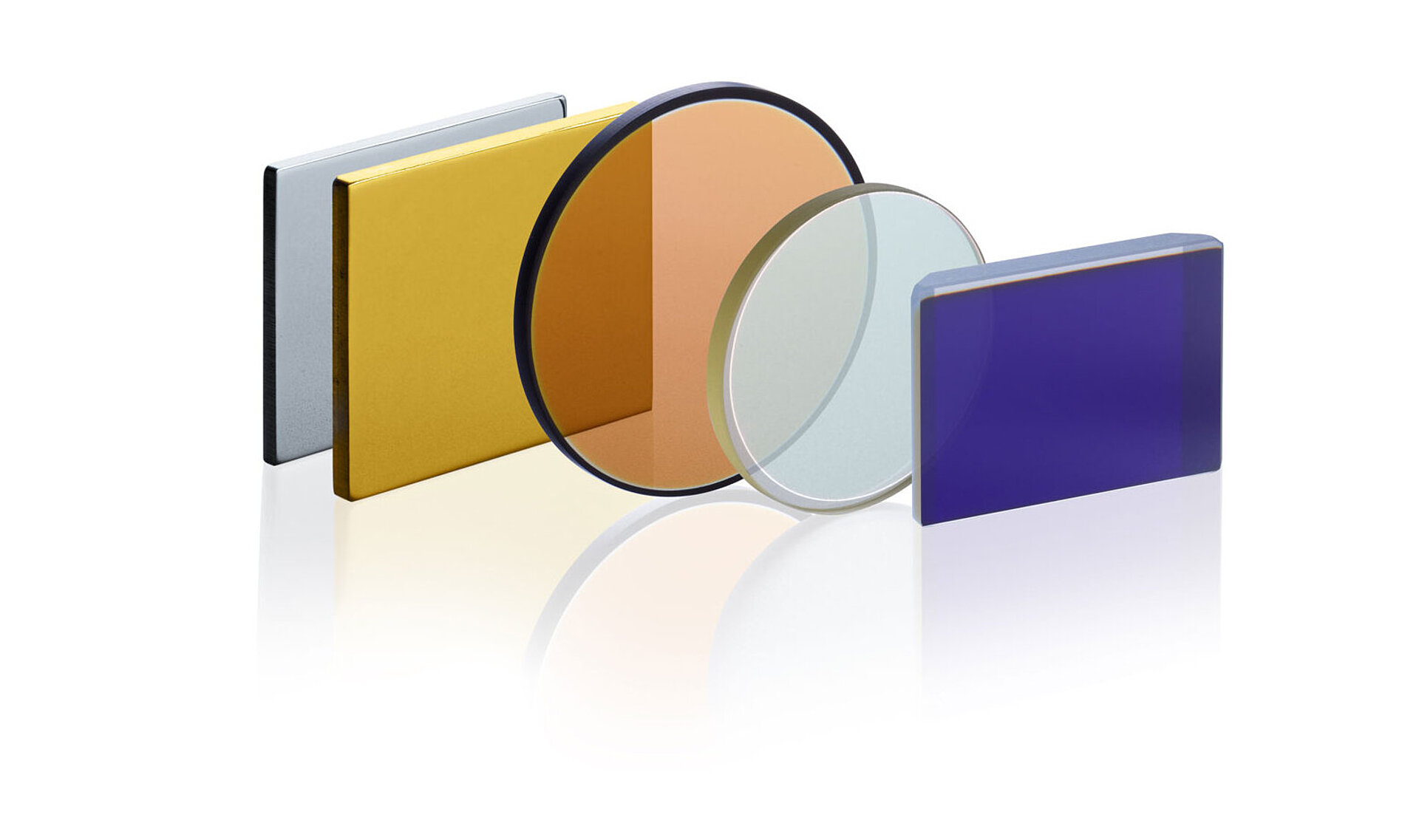

As a contract coater, we can apply URS, CMK or aluminum to your individual components.

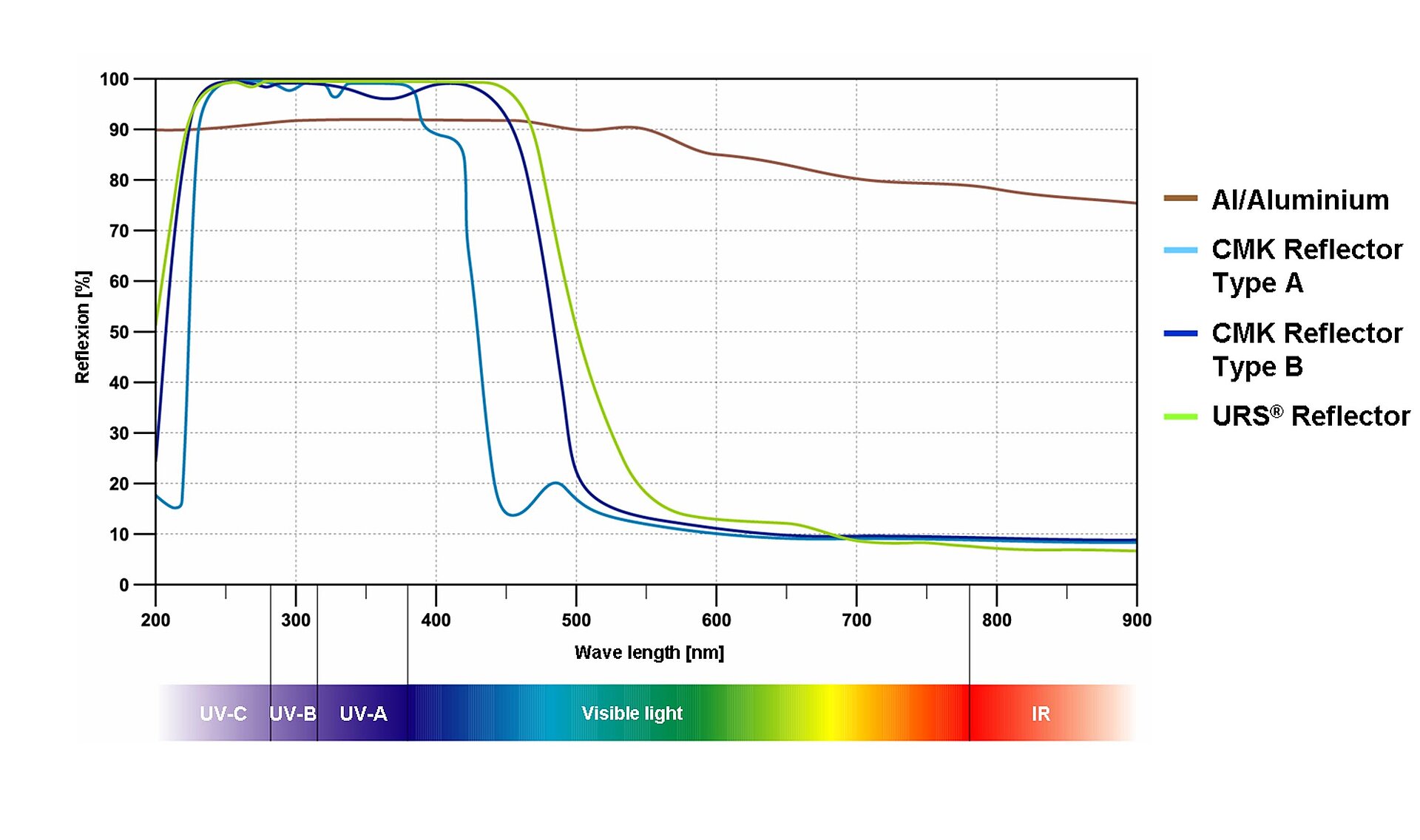

Metallization with aluminum is possible on plastic, ceramic, glass and metal. Aluminum is characterized by broadband reflectivity from the UV-C range to the NIR. Non-reflective radiation is absorbed into the substrate and converted into heat.

Metallization with aluminum can also be used to create decorative surface effects.

Our CMK mirror is a dielectric coating and therefore absorption free. By combining vapor-deposited materials, interference is created within the coating, allowing selective transmission and reflection.

Thus, high reflectivities in the UV range can be achieved; the heat-carrying VIS and IR light, on the other hand, is transmitted.

URS stands for UV-Reflection-System and extends the CMK mirror with an absorber, which transfers the heat into the substrate instead of transmitting the radiation.

This allows the energy to be kept in the reflector and, if necessary, to be conducted out of the system in a controlled manner by means of cooling.

Please feel free to contact us at any time with questions about our products or services - by phone or mail!

Customer specific coatings

In addition to our standard products, we also offer customized coatings. In-house we offer you the complete process chain: from technical consulting, layer development and simulation to sample and series coating and subsequent qualification processes - all under one roof!

Comprehensive services

Coating service means more to us than coating your product professionally and delivering it to you quickly and reliably. Our services begin long before your order and end only when the product has been delivered to you and you are satisfied with it.

- Procurement and cleaning of the substrate material

We procure the desired substrates according to your requirements and remove contamination introduced by processing or storage by means of qualified cleaning processes. In this way we achieve the highest adhesion of our coatings and avoid defects. - Samples & Series Coating

We apply metallic and dielectric coatings by means of PVD processes on our own or provided substrates - as sample coating or in series! - Mechanical processing and marking

We offer processing of your optical components before and after coating (manufacturing also tool based processes, machining / mechanical processing, polishing etc.). Components can also be marked, labeled or coded by laser engraving or diamond milling. - Documentation and delivery

If required, documentation for batches or individual pieces can be prepared and added to the delivery and the components packed, delivered or prepared for further processing in a transport-safe manner. - Analytics

Properties (optical, mechanical, etc.) are measured and documented according to your requirements. These include: Transmittance, reflectance, color value. Mechanical properties such as adhesion, friction, abrasion resistance, environmental test.

Our Technology

The PVD (physical vapour deposition) process is a thin-film technology which takes place in a vacuum and in which the layer is formed on the substrates through condensation of a material vapour.

The thicknesses of such layers are in the nanometre (nm) range. They are usually vapour-deposited one on top of another to create a multi-layer system with total layer thicknesses up to a few microns (µm), giving a very high layer quality. This creates dense, homogeneous and ductile layers which cannot be achieved by conventional methods.